Carbon2ProductAustria (C2PAT)

“Creating a novel circular cross-sectoral carbon value chain for the transformation of industry towards a climate-neutral economy”

Borealis is one of the world’s leading providers of advanced and circular polyolefin solutions and a European market leader in base chemicals, fertilizers and the mechanical recycling of plastics. In re-inventing for more sustainable living, we will keep discovering and innovating on our way forward because progress is what we need to have a better life for everyone. In Borealis views, the ‘Fit for 55 package’ is a crucial step for European industry and society to lead the global race to climate neutrality by 2050. It needs to secure Europe as a destination for investments in climate-neutral and circular technologies. To accelerate industrial electrification, the package needs to ensure that huge volumes of renewable and low-carbon energy become available as soon as possible.

Borealis agrees with the European Commission that accelerated deployment of a clean hydrogen economy will be essential to make the energy transition succeed.

As the Commission’s latest data shows, the EU Chemicals Industry is a frontrunner in the use of hydrogen. Borealis therefore welcomes the increase in the size of the Innovation Fund as well as the creation of the Important Project of Common European Interest (IPCEI) on hydrogen.

Clean hydrogen opens the door to circular and climate-neutral chemistry, which aims to utilise waste streams such as organic waste, used plastics and CO2 as feedstock instead of virgin raw materials.

Fundamental changes require all of us to join hands and work together

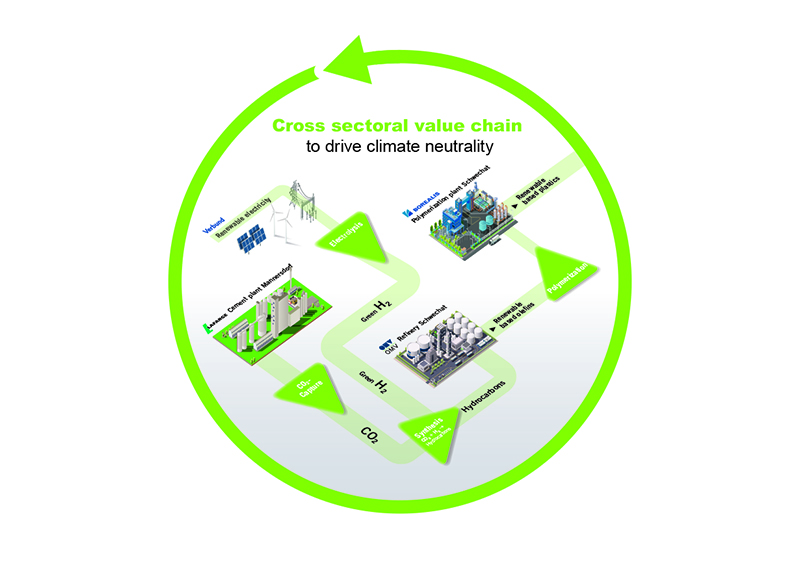

In 2020, Lafarge Zementwerke, OMV, VERBUND and Borealis co-signed a Memorandum of Understanding (MOU) for the joint planning and construction of a full-scale plant by 2030 to capture CO2 and process it into synthetic fuels, plastics or other chemicals.

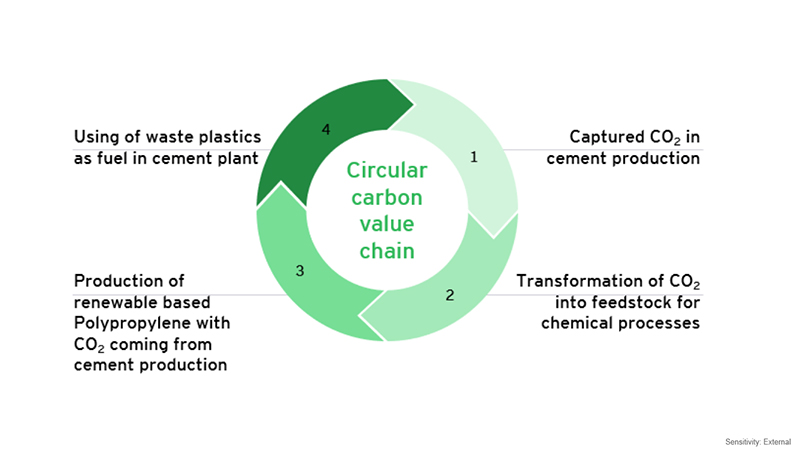

Climate neutrality, circularity and innovation in Austria are driven by establishing a cross-sectoral value chain for carbon capture. This innovative project significantly reduces emissions from cement production, establishing the greenhouse gas CO2 as a valuable raw material.

Carbon2ProductAustria (C2PAT) aims to demonstrate this novel, first-of-its-kind cross-sectoral carbon value chain at industrial scale. Industrial CO2 released during cement production is captured (10,000 tons per year for the demo plant) and transformed with green hydrogen into feedstock for a variety of renewable based chemicals and value-add plastics products.

The overall system is based on the integration and joint operation of different technologies that will be combined into one novel, holistic value chain. The facility cluster comprises a carbon capture unit, water electrolysis for the production of green hydrogen, a new synthesis route via the Reverse Water-Gas Shift Reaction and Fischer Tropsch synthesis located at the site of Lafarge’s cement plant in Mannersdorf. Intermediates will be processed at OMV and Borealis sites into olefins and, ultimately, renewable-based value-add plastics.

By demonstrating feasibility, C2PAT will elaborate innovative operational and business models to develop a scale-up concept for the carbon value chain. The key innovation is using CO2 emissions from cement production as feedstock for chemicals – an integrated and cross-sectoral approach that has never been demonstrated before.

C2PAT also demonstrates a circular economy approach in the cement and chemical sector given that renewable-based plastics can be reused and recycled in various recycling streams. C2PAT will explore the market potential for renewable-based products and develop models for control as well as for holistically optimising the overall value chain.

New know-how will be gathered to transfer the demo plant to the next scaling step: a full-scale plant which is capable of converting more than 700,000 tons of CO2 per year into renewable-based products.

Taking the next steps towards a climate-neutral economy will require the right financial as well as favourable regulatory framework conditions at the EU and Austrian national level.

With this ambitious collaboration, Lafarge, OMV, VERBUND and Borealis are showcasing an innovative and viable solution for the transformation towards a carbon neutral economy in Europe.

The joint project is designed in 3 phases: In phase 1, based on a co-signed Memorandum of Understanding, the partners are currently evaluating and developing a joint strategy for project development and funding opportunities, business modelling and process engineering. Based on the results, in phase 2, a demo plant could be technically developed and realised in the Eastern part of Austria, until 2025. Phase 3 entails the full realisation of the presented vision by scaling up to the full size of 700,000 tons of CO2 per year to be captured and used and will demonstrate the global scalability of the project.