Can data spaces support sustainability in manufacturing?

Example: Declaration of the Product Carbon Footprints

Data spaces can enable cross-company sharing of data while maintaining the data sovereignty of the companies concerned. An example where this functionality of a data space is needed and offers concrete business value is the declaration of the product carbon footprint (PCF) by companies along the supply chain.

Determining the PCF (product carbon footprint) as precisely as possible is the basis for being able to measure and influence CO2 emissions holistically and sustainably.

To calculate the PCF, a manufacturing company must determine the so-called Scope 1, Scope 2, and Scope 3 contributions to the PCF, then add them up and make the specific value available to the customer:

As part of the Scope 1 calculations, the company must determine how many direct emissions are caused by the company to manufacture the specific product.

As part of the Scope 2 calculations, the company must determine which resources, such as energy, are required by the company to manufacture the specific product.

Scope 3 includes the contribution caused by the purchased components. One could consider databases providing such so-called secondary data. However, secondary data only reflects the facts imprecisely. Therefore, primary data should be used, where the suppliers make the PCFs of the supplied components available to their customers.

Depending on the produced product only a small amount of the PCF is visible within scope 1 and 2. That is why it is crucial to include scope 3 for full transparency needed to calculate the complete PCF – from scope 1 to 3.

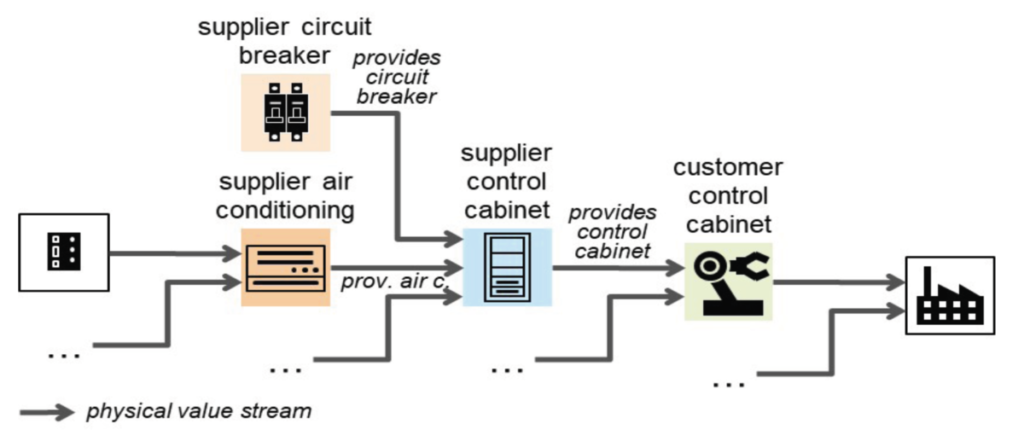

Considered Value Network

From a business perspective, the considered companies are organized in an overall supply chain. The figure shows as an example a section from such a supply chain. Each of these companies declares the PCF of their products and shares this information with their customers within the data space under consideration.

In addition, two other business stakeholders must be considered:

A software application provider offers software for managing PCFs. On the one hand, this software supports a manufacturing company in determining scope 1 and scope 2. This includes, among other things, how to allocate the overall emissions and resource consumption of a manufacturing company, which are recorded, for example, in an MES (Manufacturing Execution System) of the manufacturing company, to the specific products.

Furthermore, this software enables the PCFs declared by the suppliers to be made available in a trustworthy manner and that also the manufacturing company can make the own declared PCFs available to its customers in a trustworthy manner. In contrast to product properties such as weight, dimensions, or performance, which a customer can measure and check independently, a customer cannot do this with the PCF. And this necessary trust of a customer in a product supplier must be considered when designing the data space.

To address the core issue of trustworthiness, an additional business role of a trustworthiness services provider is considered. The core value proposition of the trustworthiness services provider is to manage information from various sources in such a way that it can be verifiably passed on to others in an unaltered manner.

The Siemens Offerings

To design the described data space, Siemens is developing the following two portfolio elements:

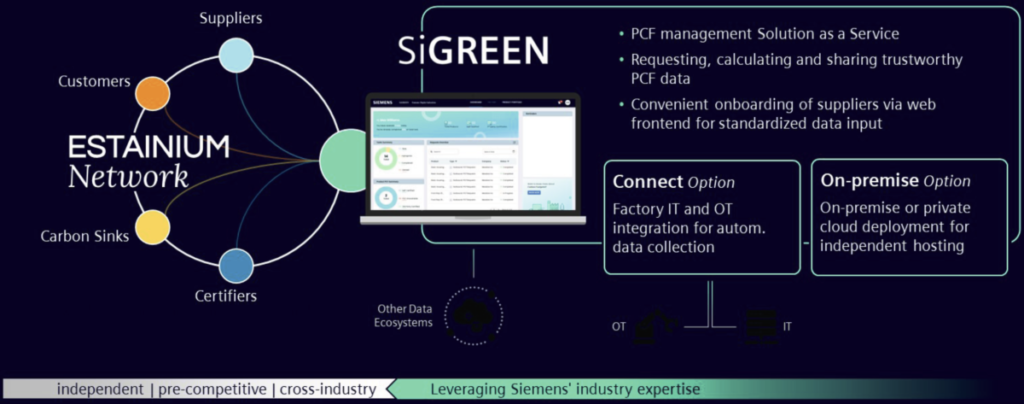

Siemens is developing a software application SiGREEN, a PCF management solution offered as a service for requesting, calculating, and sharing trustworthy PCF data. On the one hand, SiGREEN is offered as an on-premise option, in particular with the aim that customers can seamlessly integrate the software application into their existing IT infrastructure such as MES and PLM (Product Lifecycle Management) systems. This is typically a requirement of companies that offer a complex product portfolio. On the other hand, SiGREEN is also offered as a connect option. In this case, onboarding and operation of the software application are much easier. This is typically suitable for companies that offer a simple product portfolio, but it also serves as a low-effort entry offering to keep the hurdle of participation in the data space as low as possible with the option of successive expansion over time.

Together with other companies, Siemens is involved in the development of the ESTAINIUM network, which is organized cross-industry and pre-competitively. The ESTANIUM network lays, among other things, the basis for trustworthiness services, and addresses the challenge of standardizing the PCF calculation and declaration.

The Community Behind

As illustrated by the example of a data space in manufacturing to support sustainability, to design data spaces it is necessary to motivate and orchestrate a broad community of different stakeholders and to offer concrete business value. For this reason, Siemens is involved in various committees, associations, and initiatives to jointly push the design of data spaces in manufacturing industries.

Without claiming to be exhaustive, these include associations such as VDMA, ZVEI, IDTA, BDVA and GAIA-X, committees such as the Plattform Industrie 4.0, but also international standardization organizations such as IEC and ISO.

Coming back to the question “Can data spaces support sustainability in manufacturing?”

This example shows that there is a huge potential of data spaces to support sustainability in manufacturing and other domains.

At the same it shows what is needed to make data spaces functional and trustable

A clear economic benefit and impact

Mechanisms enabling a trustworthy sharing of the data

Nobody can achieve this alone. A community is needed!