Walking on two legs: mitigating climate change also means building carbon circularity with CCU technologies

The European Union (EU) made unprecedented progress in recent months towards adopting major climate legislations enabling the slashing of greenhouse gas (GHG) emissions by 55% by 2030. But the Intergovernmental Panel on Climate Change (IPCC) insists that carbon will remain a key building block for chemicals, fuels and materials, underlining our collective goal should not only be to decarbonise production processes, but to defossilise our economy: how can we defossilise hard-to-abate products that are essential to the functioning of society? Part of the answer is carbon circularity: mitigating climate change means reducing CO2 emissions, but also moving away from a linear system where we extract, produce and pollute – and towards a circular system where we avoid emissions, reuse emissions and displace fossil carbon. The good news is we have already the means to do so. Carbon Capture and Utilisation (CCU) can contribute to both reducing carbon emissions and building carbon circularity.

Climate change is accelerating. The latest IPCC report is clearer than ever: GHG emissions must drastically decrease now and our dependency on fossil resources must end. Against this background, Europe is moving forward on its climate neutrality journey: the Fit-for-55 package is progressing towards interinstitutional negotiations, and all EU institutions – Parliament, Council of the EU and Commission – are keen to build on this ambitious set of legislations to reach their climate goals.

But the EU needs not to neglect that climate action and circularity are intertwined and support investments into projects that lead to defossilisation.

‘All hands on deck’: climate action requires deploying a wide range of low carbon solutions

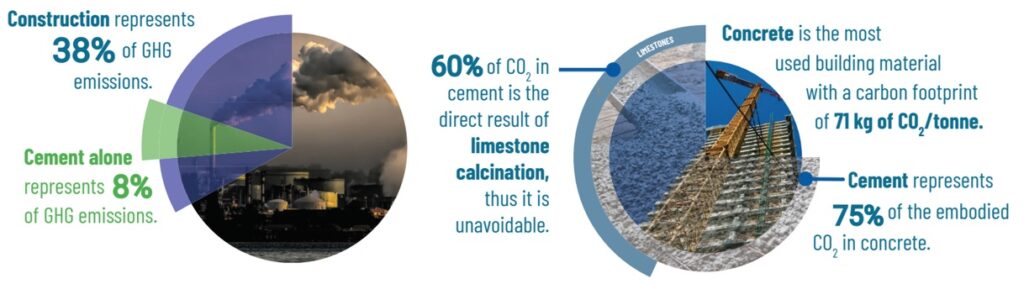

The IPCC insists that addressing climate change means mobilising several levers at the same time: phasing out coal production; reducing oil and gas dependency; deploying renewable and low carbon energy solutions; ensuring products can be repaired and avoid wasting resources. But while reducing emissions at the source is the most efficient solution to mitigate climate change, with current infrastructures and technologies, some sectors (e.g. cement, steel, aviation, maritime…) will not be able to reduce their emissions fast enough to meet global climate ambitions.

This is why a systemic approach for climate action is paramount. Europe needs to mitigate fossil extraction and emissions, with policies built around:

– Avoiding carbon emissions, by using renewable energy to replace fossil energy

– Reusing captured carbon (industrial or atmospheric) into products that displace fossil-carbon equivalents

– Removing carbon, by storing permanently emissions (either biogenic or directly captured from the air) into building materials

In practice, it means that for energy-intensive industries to reach climate targets, they must invest into switching to renewable energy supply to cover their energy needs and thus reduce avoidable emissions from fossil energy use directly at the source. But for remaining unavoidable process emissions, they need to complement those actions with other levers, like storing CO2 emissions, or reusing CO2 emissions to valorise them – the latter is what we refer to as Carbon Capture and Utilisation, or CCU.

CCU as a tool to simultaneously reduce CO2 emissions and create circularity

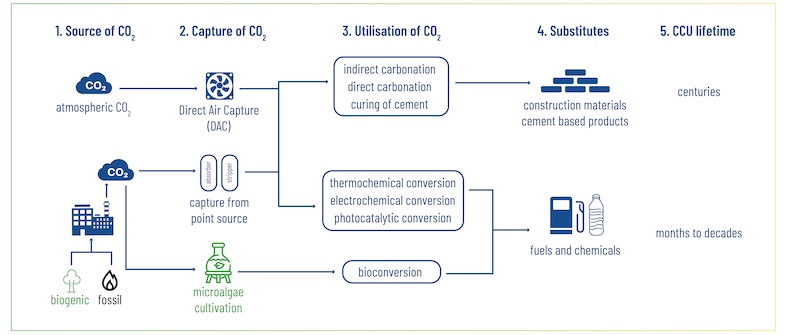

CCU is a broad concept that include all technological and industrial processes that capture carbon from industrial emissions (including biogenic) or directly from the air and convert it into products that can replace fossil-based products, both energetic and non-energetic, like fuels, plastics or construction materials.

The climate impact of CCU depends on the product lifetime, the energy required for the conversion, the product it displaces, and the CO2 source, as shown by graph 1. Depending on the pathway followed, CCU can lead to emission reductions, emission-neutral products or even carbon removals.

CCU has three essential functions:

– Helping to defossilise production, by replacing fossil carbon

– Building carbon circularity, by ensuring that unavoidable carbon emissions from one sector can be used as alternative carbon feedstock for another

– Contributing to building a circular economy by reusing waste and transforming it into products that bind CO2 permanently

CCU helps reduce CO2 emissions, it reuses waste to give it a second life, and it makes carbon more circular, in a variety of sectors and industries:

– Energy: the IPCC reports that “in the near future, global CO2 utilisation potential for fuels will be limited to 1–4.2 GtCO2yr-1, but could increase by the mid-century depending mainly on the development of a favourable policy framework”1. CCU produces drop-in renewable and low carbon fuels which can replace fossil fuels in a variety of applications (energy-intensive industry, aviation, maritime…)

– Chemicals: the IPCC report also refers to studies showing that “CCU has the technical potential to decouple chemical production from fossil resources, reducing annual GHG emissions by up to 3.5 Gt CO2-eq in 2030”2. It means CCU can help to defossilise (rather than decarbonise).

– Construction: studies show that “all considered CCU technologies for mineralisation could reduce climate impacts over the entire life cycle based on the current state-of-the-art and today’s energy mix. Up to 1 Gt per year of the cement market could be substituted by mineralisation products” 3. CCU enables to create a double circularity for gas and solid waste recycling via CO2 mineralisation, but also to replace fossil fuels to fire e.g. cement kilns

Those different applications show that CCU is crucial for avoiding fossil carbon, displacing fossil carbon, and for building circular systems.

But to do so, CCU needs the right framework and support. EU institutions have promoted CCU in many legislations – by incentivising the binding of carbon in construction products in the ETS revision, by setting quotas for the use of CCU fuels in REDIII, ReFuelEU Aviation, FuelEU Maritime, or by promoting the use of renewable carbon in chemicals and plastics in the Sustainable Carbon Cycles Communication.

Recent declarations from EU officials tend to describe CCU technologies as a necessary transitional solution to reduce emissions, but only in the short to medium term, arguing that valorising emissions would only mean delaying them. The underpinning idea is that CCU does not contribute to reducing emissions, because in some CCU applications, the CO2 is eventually emitted, often benchmarking CCU to the linear approach of CCS, where CO2 is geologically stored.

But benchmarking CCU to CCS is not correct: CCU should not be assessed only looking at the duration or the storage capacity in a product, but rather with a comprehensive life-cycle analysis of the CO2-based product generated and its comparison to its fossil counterpart. Through avoidance and displacement, CCU contributes to ending a linear vision of the economy, and building industrial symbioses – enabling cooperation between CO2 emitters, CO2 converters, end-product users – to reduce emissions across the board.

CCU is neither a stand-alone solution nor a silver bullet to mitigate climate change. CCU is meant to defossilise production systems, and needs to be rolled-out hand-in-hand with other low carbon solutions and climate actions – electrification, energy efficiency, sobriety efforts, etc.

Climate neutrality will be circular, or it will not be

Climate neutrality means breaking up with the fossil civilisation, which takes root in a linear approach: extracting fossil resources, exploiting them, transforming them into products, and throwing them away. CCU can contribute to changing this paradigm by reusing carbon from unavoidable emissions, and by reusing existing waste to sequester carbon.

As an example amongst many others, one illustration is the circular footpath built with Carbstone clinkers in Ghent (Belgium)4. These were made using the Carbstone technology developed by VITO together with the company Orbix. The bricks are made by allowing residual products from steel production (steel slags) to react with CO2. It means that no new raw materials are used, and that CO2 is permanently bound, with 1 m³ of Carbstone bricks storing a net 350 kg of CO2.

Investing into carbon neutrality requires investing into circularity. EU policy-makers should make sure to break down silos between climate and circular economy legislations. For example, the revision of waste rules at EU level should include climate targets ; the Sustainable Products Initiative should include binding targets for CO2-based products.

The endgame is clear: we must create virtuous ecosystems to help restoring sustainable carbon cycles, enable for renewable carbon to be used as alternative feedstock and putting fossil resources to rest. CCU can help us walking on two legs: building both a circular and climate neutral European society.

_________________________________________________________________

1 Source: IPCC AR6 WG3 Chapter 6

2 Source: Kätelhön et al. (2019) / IPCC AR6 WG3 Chapter 11

3 Source : Ostavari et al., 2020, Di Maria et al., 2020, Hills et al., 2020

4 https://vito.be/en/news/first-footpath-constructed-carbstone-clinkers